Mobile SCADA/ HMI

Customer:

Torrance Casting

Scope:

In 2016, the foundry started using Ignition by Inductive Automation as their SCADA/ HMI solution for their speed mullor sand mixing process. Over the years Ignition has spread throughout the plant from sand mixing and black water control machinery to plant conveyor motor bearing health, water flow totalizers, and natural gas usage. Supervisors were finding that visibility of the system was important for system performance, but they were wanting to control and monitor key parts of the process on the shop floor so they can be closest to the equipment and the people.

Design:

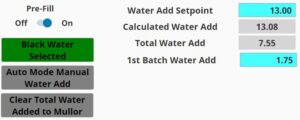

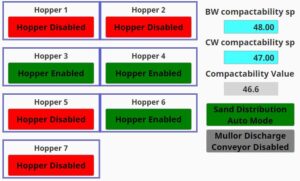

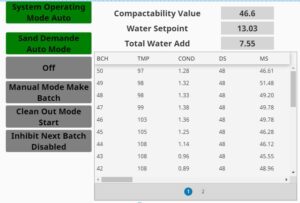

The foundry’s SCADA system, Ignition, was found to be the perfect tool. Utilizing Ignition’s Perspective application, a mobile application was built for these key parts of the  process. A tablet with wifi connectivity was purchased for this application. System overview, sand distribution, water control, alarming, and navigation pages were created with Perspective. Tabular test result lab data was added to the system overview page so the batch test results could also be viewed on the fly right after the batch was completed. With this information in hand the other processes could be changed or alerted based on these test results.

process. A tablet with wifi connectivity was purchased for this application. System overview, sand distribution, water control, alarming, and navigation pages were created with Perspective. Tabular test result lab data was added to the system overview page so the batch test results could also be viewed on the fly right after the batch was completed. With this information in hand the other processes could be changed or alerted based on these test results.

Results:

Now Torrance staff have the ability to control key parts of the process on the shop floor so they can be closest to the equipment and the people performing the work. This allows for tighter process control and better sand quality.