Production Takt Time Control

Customer: Heat Exchanger Manufacturer

Customer: Heat Exchanger Manufacturer

Project Scope: Part of the manufacturing process for heat exchangers is to assemble the water box or header. This requires preparation, pulling parts, welding in many stations, and testing. The current method for scheduling, tracking, and utilizing work cell resources at the designed takt time was all done by a scheduler and a foreman with a clipboard. Coordination and timing of production builds was difficult and labor intensive.

Project Design: Industrial Automation was contracted to design and program an Ignition SCADA-driven software application to query production data, display scheduled work, and provide a system control interface. Large wide-screen monitors were installed in the work cells to display the production work orders. Supervisors and managers were given access to a networked client application for modifying and controlling the SCADA system at any networked computer or mobile device. The system is also set up to run if the network is down or connection to the SQL database is offline.

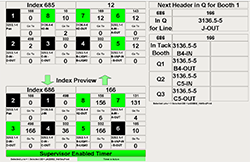

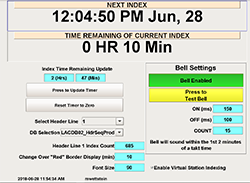

Production scheduling and work order resource data is loaded into a database. A specified takt time or index is programmed into the system, which sets the pace for work to flow from station to station or resource to resource. When an index time is close to expiring, the production screen will change colors and an annunciator will sound, indicating the change to the production staff. When the index expires and a new index is started, the new production work order and work cell information is displayed based on the SQL query. The supervisor has access to another screen that allows “virtual” work cell updates to be made on the fly, gives them the ability to view the next and previous works orders, and provides the ability to pause the system takt timer. Production staff has access to “Timer Adjustments,” “Scheduling,” “Data View,” and the “Users” screens. The “Timer Adjustments” screen allows access to update and zero out the takt timer, in addition to displaying header line selection annunciator settings, SQL data query settings, and some production screen dynamic formatting settings. The “Scheduling” screen allows production staff to add, modify, or delete schedules for index breaks or “pauses.” The “Data” screen displays an active and expired SQL query in table format. The “Users” screen allows production staff with proper credentials to add, modify, or change user credentials for access to different screens or screen content.

Production scheduling and work order resource data is loaded into a database. A specified takt time or index is programmed into the system, which sets the pace for work to flow from station to station or resource to resource. When an index time is close to expiring, the production screen will change colors and an annunciator will sound, indicating the change to the production staff. When the index expires and a new index is started, the new production work order and work cell information is displayed based on the SQL query. The supervisor has access to another screen that allows “virtual” work cell updates to be made on the fly, gives them the ability to view the next and previous works orders, and provides the ability to pause the system takt timer. Production staff has access to “Timer Adjustments,” “Scheduling,” “Data View,” and the “Users” screens. The “Timer Adjustments” screen allows access to update and zero out the takt timer, in addition to displaying header line selection annunciator settings, SQL data query settings, and some production screen dynamic formatting settings. The “Scheduling” screen allows production staff to add, modify, or delete schedules for index breaks or “pauses.” The “Data” screen displays an active and expired SQL query in table format. The “Users” screen allows production staff with proper credentials to add, modify, or change user credentials for access to different screens or screen content.

Project Results: The Production Takt Time Control project delivered the simplicity, reliability, and data visibility as promised. The management team is pleased with the installation and the ability to update and make changes on the fly. In addition, knowing that the Ignition system is not dependent on any specific operating system and has the ability to operate when the network is down allows for future expansion and enhances production reliability.

Project Results: The Production Takt Time Control project delivered the simplicity, reliability, and data visibility as promised. The management team is pleased with the installation and the ability to update and make changes on the fly. In addition, knowing that the Ignition system is not dependent on any specific operating system and has the ability to operate when the network is down allows for future expansion and enhances production reliability.